Based in Indianapolis

Forging A Sustainable Future Ahead

Bryant, a company based in the United States, is dedicated to forging a sustainable future ahead. At our residential business headquarters in Indianapolis, Indiana, we prioritize continuous improvement and innovation. While boasting a rich legacy in the HVAC industry, we remain steadfast in our pursuit of improvement. With over a century of perfecting home comfort, our journey is guided by our knowledgeable teams in the United States.

Product Development

Our U.S.-based product development hub is the home of our design and testing, with a significant portion of manufacturing transpiring in Indianapolis and Collierville, Tennessee.

Innovative Engineers

Central to our core is assembling a top-tier organization. Our Indianapolis headquarters houses forward-thinking engineers who craft impactful solutions for both people and the environment.

Model Shop

Our model shop empowers our engineers to create virtually any concept using prototyping components, test units, and fixtures for all Bryant products.

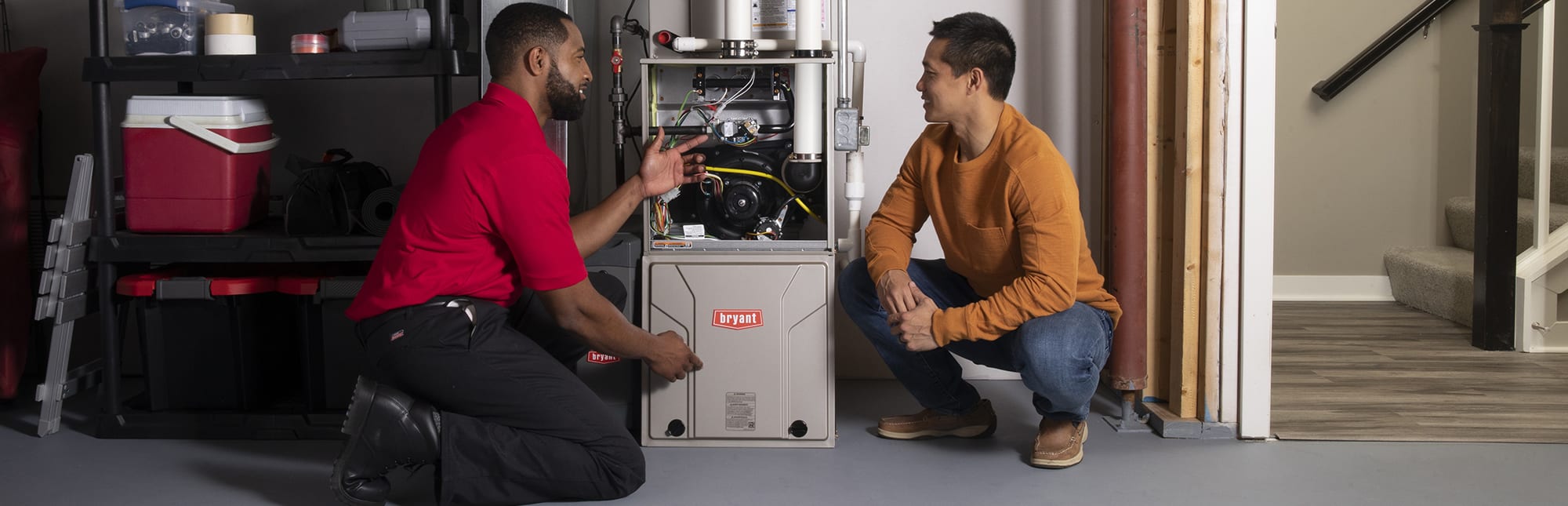

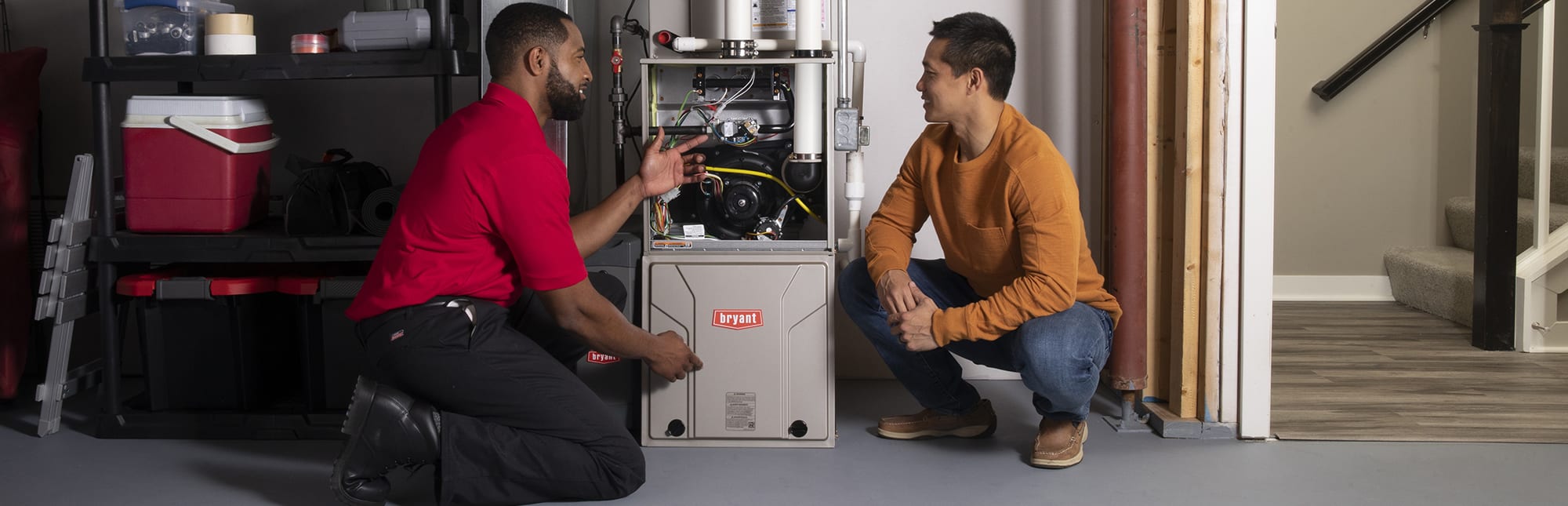

Gas Furnace Factory

Our Indianapolis factory stands as one of the largest gas furnace plants globally, spanning close to 550,000 square feet. Within our Furnace Reliability Lab, rigorous testing ensures enduring performance, fostering greater peace of mind for homeowners.

Vibration Tests

Within this lab, we meticulously analyze vibrations stemming from moving components in HVAC systems, including motors, fan blades, blowers, and compressors. Since prolonged vibration can induce component fatigue and eventual failure, we implement design modifications based on precise measurements. This proactive approach assures homeowners of the utmost innovation and reliability in Bryant products.

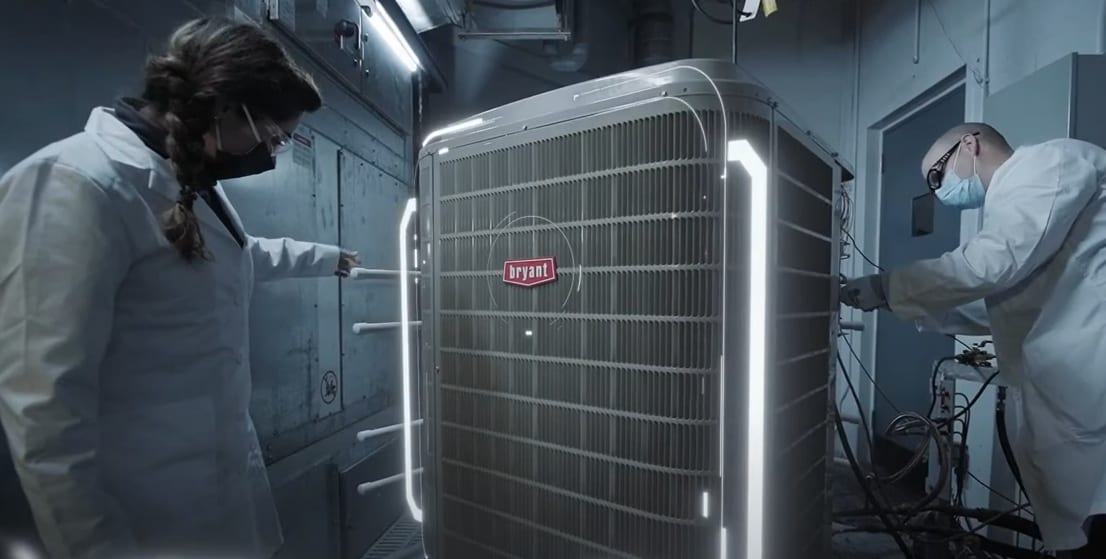

Psychrometric Test Chambers

This is where we study how temperature and humidity affect our products’ performance and their ability to heat and cool your home. By replicating indoor and outdoor temperature and humidity conditions, we’re able to measure our products’ performance to ensure they’re reliable, to optimize efficiencies, and to test for UL certification.

Continuous Improvement

We make it a point to actively embrace feedback from our distributors, dealers, and homeowners, seamlessly integrating it into our ongoing process of improvement. By meticulously testing and analyzing returned parts, we fine-tune our product designs to tackle any issues that have been identified. As an example, when we receive feedback about a coil leak, we put it through rigorous water submersion testing to precisely pinpoint, validate, and resolve the root cause, thereby bolstering the effectiveness of our solutions.

Manifold Robot

Automation helps us ensure uniformity as we design and build new products. Robots play a critical role in this endeavor. Our manifold robot assembles the gas valve and orifices to the manifold to create the manifold assembly. This process has improved efficiency and productivity, while notably growing quality.